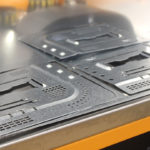

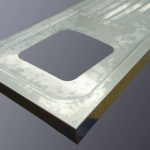

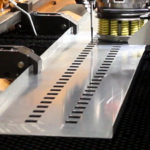

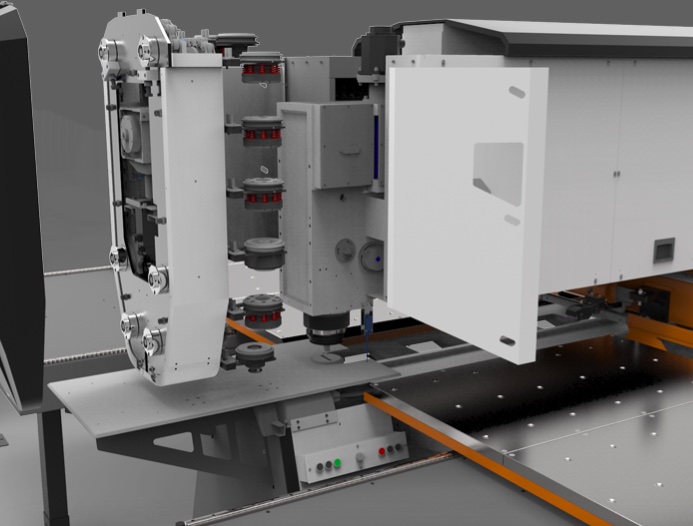

Customize the configuration of the Vertical Turret

The TP Zeta turret punching machine features TRUMPF or TECHNOLOGY style tools. You can choose one of the available configurations or customize each single station with standard, special and/or multi-tool tools.

BASIC

1

AUTO-INDEX TOOLS

TOP

1

AUTO-INDEX TOOLS